Unless the tuning machines got damaged from a fall or hit, it is virtually impossible that Duesenberg Z-Tuners are the source of a problem regarding the stability of your tuning.

The important part regarding tuning stability is actually how you string the guitar.

Firstly, we recommend 2-3 windings of strings on the tuner shaft for the wound strings (E, A, D) and 3-4 windings for unwound strings (G, B, e).

Secondly, it is very important to stretch the windings on the shaft tight. If you don't do that, your guitar will detune constantly.

A good technique for string stretching is to grab the string as shown here and stretching it around five to ten times. Retune every time you stretch the string. After at least five times, you should notice that the tuning becomes more stable. Keep stretching until the strings pitch does not change anymore.

You can be rough on the E, A and D string but please be a little more careful on the thinner unwound strings so you don't break them.

A good stringing is the starting point for it all. If the guitar is not strung properly, a stable tuning is hard to get.

The nut is the little part at the upper end of the fretboard which guides the strings from the tuners to the bridge. It defines and influences a lot of things and is one of the most important pieces on your guitar.

If done wrong, it also is one of the main factors causing detuned strings. In a bad nut, the strings get jammed on sharp edges and tight slots so they cannot return to their correct position after using the tremolo or even just doing finger vibrato or bendings.

Good news again: we spend a lot of time and care in our factory in Germany hand-filing these nuts to fit your guitar so that you don't have to worry about it.

What you do need to know, though, is that a really well worked nut is always fitted to a certain string gauge. We factory fit our instruments with 10/50 strings because it's an awesome gauge for the scale length - really punchy and responsive.

If you restring your Duesenberg with lighter strings, it generally does not cause problems. Much thicker strings, like 12 or 13 gauge, might get jammed in the smaller slots of the nut. If that happens, you should have the nut re-filed by a luthier.

Also, we recommend to apply a tiny little bit of silicone oil on the slots of the nut at least once a year. Strings are exposed to sweat and dirt which will sooner or later collect in the slots of the nut, so it's important to clean and lubricate it once in a while.

Less is absolutely more – too much of it only collects dust and dirt.

There is not much to talk about here. Don't waste your money on cheap strings - they aren't worth it. We recommend genuine Duesenberg strings, of course. You can get them at any official Duesenberg retailer or directly through our Webstore.

As far as replacing strings goes: some people do it monthly, some do it weekly. Some professionals do it daily, while others never do it.

If you are after optimal performance and tone you should do it once the strings begin to sound dead and don't "ring" anymore.

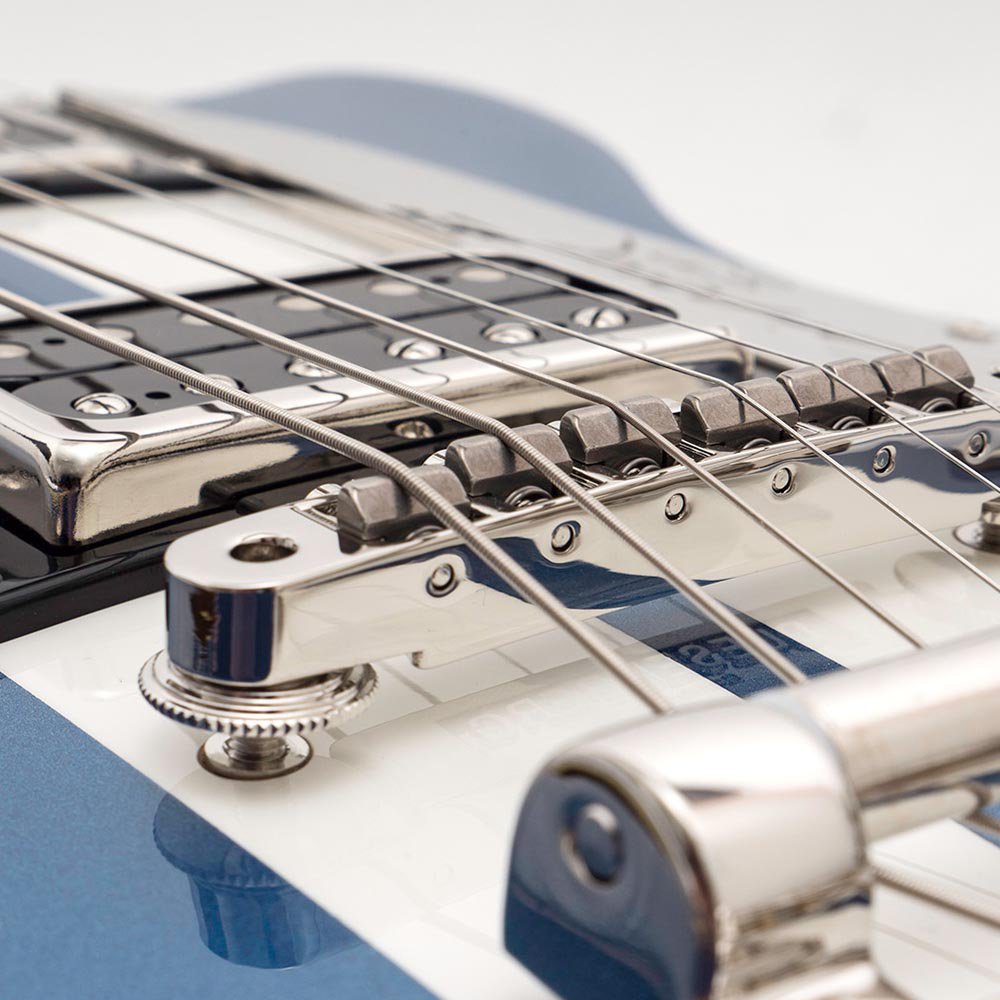

The bridge is the other important friction point for the strings besides the nut. Therefore, it is important to reduce friction in a way that does not compromise on resonance transfer to the body.

We developed a system which allows the bridge to slightly rock back and forth a bit, compensating for the rubbing of the strings on the saddles of the bridge.

If you want to adjust the height of the bridge, make sure that the studs which hold the bridge in place only reach half way into the bridge from the bottom. This will allow the bridge to keep moving properly.

We generally do not recommend roller bridges. They only work well when friction between the roller and bridge is reduced as much as possible which also results in less resonance transfer to the body.

The tremolo is the opposite side counterpart of the tuners and we spent years and years designing it and making it work. It has a lot of useful features. Easy string attachment and full adjustability of the tremolo arm are the two most important ones.

When it comes to tuning stability, the only thing important to know is that the strings are led around the first and under the second roller. The second roller, called the "downholder roller", generates pressure on the bridge which is important for tone.